TRUST

PRINCIPLE.

Optics & Crystals PROVIDED BY SKP

- first_uid = 89, post_uid = 105 active_uid = 105

- Beamsplitter first_uid = 89, post_uid = 105 active_uid = 105

- Crystals first_uid = 89, post_uid = 105 active_uid = 105

- Crystalline Mirror first_uid = 89, post_uid = 105 active_uid = 105

- Femtoline Optics first_uid = 89, post_uid = 105 active_uid = 105

- Filters first_uid = 89, post_uid = 105 active_uid = 105

- Grating (VPH) first_uid = 89, post_uid = 105 active_uid = 105

- GRIN Lens first_uid = 89, post_uid = 105 active_uid = 105

- Lens & Mirror first_uid = 89, post_uid = 105 active_uid = 105

- MgO:PPLN Crystal first_uid = 89, post_uid = 105 active_uid = 105

- PPLN Waveguides first_uid = 89, post_uid = 105 active_uid = 105

- Prism first_uid = 89, post_uid = 105 active_uid = 105

- SAM/SOC/SA first_uid = 89, post_uid = 105 active_uid = 105

- Scan Lens first_uid = 89, post_uid = 105 active_uid = 105

- Ti:Sapphire Crystal first_uid = 89, post_uid = 105 active_uid = 105

- Waveplate & Window first_uid = 89, post_uid = 105 active_uid = 105

- Others

Crystalline Mirror

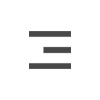

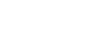

We offer ultrahigh performance single-crystal optical coatings and novel manufacturing processes including adhesive-free direct bonding services that are tailored to meet (and ideally exceed) your unique requirements. Our expertise in optical system design and advanced microfabrication techniques enables you to achieve unprecedented levels of performance to meet your demanding specifications. With our substrate transfer and direct bonding processes we manufacture discrete optics and optical subassemblies with unprecedented levels of performance. The result: Semiconductor Supermirrors: The absolute highest quality coating on an optimized substrate.

● xtal stable

| Item | xtal stable |

|---|---|

| Center wavelength | 900nm |

| Optical absorption | <1ppm |

| Optical scatter | >5ppm |

| Radious of curvature | 10Cm |

| Reflectivity | Typically >99.99%, >99.999% achievable |

| Loss angle | <4 × 10⁻⁵ at 300 K, <5 × 10⁻⁶ at 10 K |

| Coating material | Single-crystal GaAs/AlGaAs |

| Coating surface quality | 1 Å RMS micro-roughness |

| Substrate material | Typically fused silica, other materials available |

| Substrate diameter | 0.5 - 1 inch (12.7 - 25.4 mm), other sizes available |

| Surface flatness | <0.10 wave P-V measured @ 633 nm |

| Durability | Similar to fused silica, cleaning instructions provided on request |

● xtal mir

| Item | xtal mir |

|---|---|

| Center wavelength | 2um |

| Optical losses | < 40 ppm (scatter + absorption) |

| Bandwidth | 200 nm FWHM |

| Optical transmission | Tunable, per customer request |

| Coating material | Single-crystal GaAs/AlGaAs |

| Substrate material | Typically single-crystal silicon, other materials possible |

| Substrate diameter | 0.5 - 1 inch (12.7 - 25.4 mm), other sizes available |

| Radius of curvature (ROC) | >0.1 m |

| Surface quality | <5 Å RMS micro-roughness |

| Surface flatness | <0.10 wave P-V measured @ 633 nm |

| Durability | Similar to fused silica, cleaning instructions provided on request |

● xtal therm

| Item | xtal therm |

|---|---|

| Center wavelength | 90nm~5000nm |

| Optical losses | < 5 ppm (scatter + absorption) |

| Coating thermal conductivity | > 30 W / (m·K) |

| Optical transmission | Tunable, per customer request |

| Coating material | Single-crystal GaAs/AlGaAs |

| Substrate material | Diamond, SiC, or other materials possible |

| Coating area | 200 mm diameter maximum, custom geometries possible |

| Surface flatness | <0.10 wave P-V measured @ 633 nm |

| Radius of curvature (ROC) | >0.1 m |

| Surface quality | <5 Å RMS micro-roughness, surface overcoat optional |

| S2 surface | AR coated for transmissive optics, super-polished, rough-cut, or metal coatings also available |

| Durability | Similar to fused silica, cleaning instructions provided on request |

● xtal custom - Fully customized solutions for direct-bonded components

>> Example applications made possible or improved by direct bonding:

● Semiconductor active regions on SiC and diamond for thermally-optimized saturable absorbers and high-power emitters

● Electrically-conductive interface layers between single-crystal semiconductors

● Laser disks directly bonded to polished heat sink materials

● Buried dielectric layers between single-crystal materials and thin films

● Integration of non-lattice-matched semiconductor heterostructures

● Semiconductor films on “soft” materials

● Joining dielectric and semiconductor layers for silicon and integrated photonics

● Simplify manufacturing by eliminating film stress

| Item | xtal custom |

|---|---|

| Example material | Fused silica, Sapphire, Ti:Sapphire, GaAs, SiC, Diamond, YAG, YVO4, ete. |

| Size | <5mm ~ 200mm |

| Thickness | >1um ~ 30mm |

| Radious of curvature | 10Cm |

제품소개

PRODUCTS