TRUST

PRINCIPLE.

Opto-mechnicsPROVIDED BY SKP

- first_uid = 91, post_uid = 91 active_uid = 91

- Carbon Fiber Breadboard first_uid = 91, post_uid = 91 active_uid = 91

- Optical Table & Breadboard first_uid = 91, post_uid = 91 active_uid = 91

- Opto-mechanics Components first_uid = 91, post_uid = 91 active_uid = 91

- Opto-mechanics Devices first_uid = 91, post_uid = 91 active_uid = 91

- Kits & Lab Supplies first_uid = 91, post_uid = 91 active_uid = 91

- Manual Stage first_uid = 91, post_uid = 91 active_uid = 91

- Motorized Stage first_uid = 91, post_uid = 91 active_uid = 91

- Multi-Axis Stage first_uid = 91, post_uid = 91 active_uid = 91

- Actuator & Adjuster first_uid = 91, post_uid = 91 active_uid = 91

- Motion Controller first_uid = 91, post_uid = 91 active_uid = 91

- Others

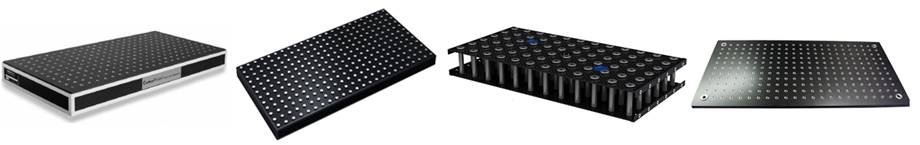

Carbon Fiber Breadboard

Optical Breadboards made from Carbon Fiber Reinforced Polymer (CFRP) provide a similar thermal stability to Super Invar but at a lower cost and are inherently non-magnetic. Since time immemorial, steel breadboards have been the only game in town. However, structures made CFRP have been used in the aerospace and space industries for many years due to their low weight, high strength, excellent thermal stability and low resonant frequencies.

The boards are available with flat working surfaces or alternatively with protruding head inserts, which allow a high degree of flatness by grinding of insert faces. To cover various requirements, our boards are offered in four different versions:

● EC-Version (Economy Series)

Cost effective series of breadboards based on honeycomb or sandwich panels with thick CFRP cover plate. Stiffness and thermal stability can be adjusted by varying CFRP plate thickness on top/bottom side of the board.

| Technical specifications | |

|---|---|

| Dimmension | Typical breadboard sizes are available, maximum size 2000 x 2500 mm |

| Thickness | Typical thickness ranges from 25, 50, 75 to 100 mm or according to structural requirements or customer needs |

| Flatness | Flatness of entire mounting surface EC- Version ≤ 0.05 mm , ECI- Version ≤ 0.2 mm |

| Mounting Grid | Typical mounting grid: 25×25 mm, 50×50 mm or customized |

| Mounting Holes | Metric and imperial threads, inserts are made from stainless steel, Aluminium, Titanium or INVAR |

| Damping | Nominal damping |

| Thermal Expansion | Lateral directions CTEx,y = 2.5 · 10 E-6 [mm/mm·K] @ 273 K for plane plate |

| Stiffness | Nominal stiffness |

| Weight | Area weight approximately 14 kg/m² (50 mm grid) |

| Design | – Honeycomb structure with skins made from multi-layered Carbon fiber fabrics cured with Epoxy Resin – Skins are designed typically to meet quasi-isotropic behaviour or according to structural/ thermal requirements – High rigidity Aluminium or closed cell foam |

| Top Side | Single inserts according to mounting grid, with first inserts 25 mm from edges or customized and sealed mounting holes |

| Bottom Side | Single inserts with through holes at corners, 25 mm from edges or customized |

| Sidewalls | Carbon fiber plates with edge protection profiles |

| Ventilation | For vacuum applications core materials are ventilated |

● AD-Version (Advanced Series)

| Technical specifications | |

|---|---|

| Dimension | Typical breadboard sizes, maximum size 2000 x 2500 mm |

| Thickness | Typical thickness ranges from 25, 50, 75 to 100mm or according to structual requirements or custom needs |

| Flatness | Flatness of entire mounting surface SA- Version ≤ 0.05 mm , SAI- Version ≤ 0.2 mm |

| Mounting Grid | Typical mounting grid: 25×25, 50×50 mm or customized |

| Mounting Holes | Metric or imperial threads, inserts made from stainless steel, Aluminium, Titanium or INVAR |

| Damping | Norminal damping |

| Thermal Expansion | Lateral directions CTEx,y = 2.5 · 10 E-6 [mm/mm·K] @ 273 K for plane plate Vertical directions CTEx,y = -0.1 ÷ 0.5 10 E-6 [mm/mm·K] @ 273 K for CFRP tube in axial direction |

| Stiffness | Nominal stiffness |

| Weight | Area weight approximately 19 kg/m² (50mm grid) |

| Design | – Plates are designed typically to meet quasi-isotropic behaviour or according to structural/thermal requirements – Plate structure with space tubes and/or ribs – Tubes are designed typically for high axial stiffness |

| Top Side | Single inserts according mounting grid, with first inserts 25 mm from edges |

| Bottom Side | Single inserts with through hole at corners, 25 mm from edges or customized |

| Sidewalls | Edge protection profile, side walls on demand |

| Vacuum | Suitable |

| Cleanroom | Suitable |

● CA-Version (Full Carbon Series)

Boards of the CA-series are entirely made from Carbon Fiber Reinforced Polymer (CFRP). The top and bottom plates consist of CFRP shells structurally joined by tubes and/or ribs made from CFRP. In addition to the advantages of the AD-series, boards of the CA-series allow the integration of optical / electronic components inside the stiff carbon shell and easy routing of wires and optical fibers. Breadboards can be ordered customized and with removable side-walls.

| Technical specifications | |

|---|---|

| Dimension | Typical breadboard sizes, maximum size 2000 x 2500 mm |

| Thickness | Typical thickness ranges from 25, 50, 75 to 100 mm or according to structural requirements or customer needs |

| Flatness | Flatness of entire mounting surface CA- Version ≤ 0.05 mm , CAI- Version ≤ 0.2 mm |

| Mounting Grid | Typical mounting grid: 25×25, 50×50 mm or customized |

| Mounting Holes | Metric and imperial threads, inserts made from stainless steel, Aluminium, Titanium or INVAR |

| Damping | Nominal damping |

| Thermal Expansion | Lateral directions CTEx,y = 2.5 · 10 E-6 [mm/mm·K] @ 273 K for plane plate Vertical direction CTEz = -0.1 ÷ 0.5 E-6 [mm/mm·K] @ 273K for CFRP tube in axial direction |

| Stiffness | Nominal stiffness |

| Weight | Area weight approximately 19 kg/m² (50 mm grid) |

| Design | – Plate structure with spacer tubes and/or ribs. – Plates are designed typically to meet quasi-isotropic behaviour or according to structural/thermal requirements – Tubes are designed typically for high axial stiffness |

| Top Side | Single inserts according mounting grid, with first inserts 25 mm from edges |

| Bottom Side | Single inserts with through hole at corners, 25 mm from edges or customized |

| Sidewalls | Edge protection profiles, side walls on demand |

| Vacuum | Suitable |

| Cleanroom | Suitable |

● SL-Version (Slim Line Series)

Slim Line Breadboards of SL-series offer high stiffness at minimum thickness. The breadboards are entirely made from Carbon Fiber Reinforced Polymer (CFRP) and constist of a top and bottom plate. The plates are optionally structurally decoupled by a damping foil which is laminated in-between. Typically breadboards of SL-series are used as additional platforms mounted on top of a larger breadboard or an optical table.

| Technical specifications | |

|---|---|

| Dimension | Typical breadboard sizes, maximum size 2000 x 2500 mm |

| Thickness | Typical thickness ranges from 5 to 25 mm |

| Flatness | Flatness of entire mounting surface SL- Version ≤ 0.05 mm , SLI- Version ≤ 0.2 mm |

| Mounting Grid | Typical mounting grid: 25×25, 50×50 mm or customized |

| Mounting Holes | Metric or imperial threads, inserts made from stainless steel, Aluminium, Titanium or INVAR |

| Damping | Optimized damping |

| Thermal Expansion | Lateral directions CTEx,y = 2.5 · 10 E-6 [mm/mm·K] @ 273 K for plane plate |

| Stiffness | Nominal stiffness |

| Weight | Area weight approximately 22 kg/m² (25mm grid) |

| Design | – Plates are designed typically to meet quasi-isotropic behaviour or according to structural/thermal requirements – Plate structure with optional damping foil in-between |

| Top Side | Single inserts according mounting grid, with first inserts 25 mm from edges |

| Bottom Side | Single inserts with through hole at corners, 25 mm from edges or customized |

| Sidewalls | None |

| Vacuum | Suitable |

| Cleanroom | Suitable |

제품소개

PRODUCTS